Well, I was fortunate enough to see the work in progress, and I took some handy pics as an example to someone who is interested in having a cage or roll bar built in their 1g DSM

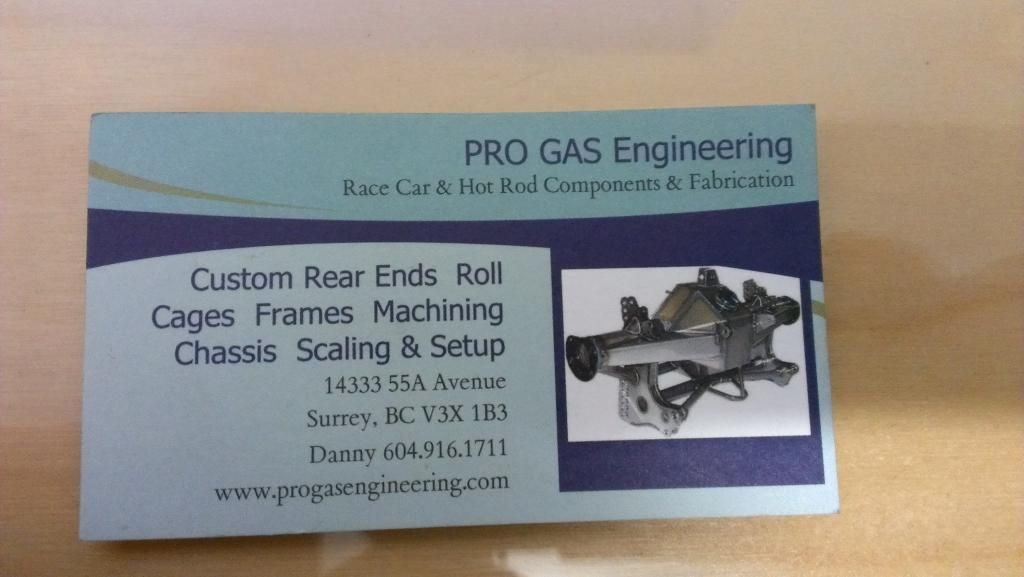

This also stands as a review of the quality job done by Dan (owner/operator) @ Pro Gas Engineering

To start this off, the guy is legit. and dont take shit. hahaha

Dan is excellent at what he does, and he uses quality tools and cad programs to map out the more complex jobs that he does.

now, anyone can throw some pipe up and weld it. But Dan offers CNC products too. He uses software to map out the cage and with all axis of the bends accounted for, all the pipe lengths, bend locations, offsets of bends etc.

I opted to run the front pillar bars down infront of the stock dash bar.

Some people go for the hidden look and they clear a path behind the dash bar and sqeak a pipe down with some funky bends.

I decided Ide make my job easier, aswell as Dans. The front bars are not going to be intrusive at all, I didnt need to take out my windshield, And Ill just have to trim the dash accordinly. Ill take my time and make it look as best as I can. But honestly.... who can criticize a car that is more go than show! atleast Im putting a dash back in!

Heres some pics!